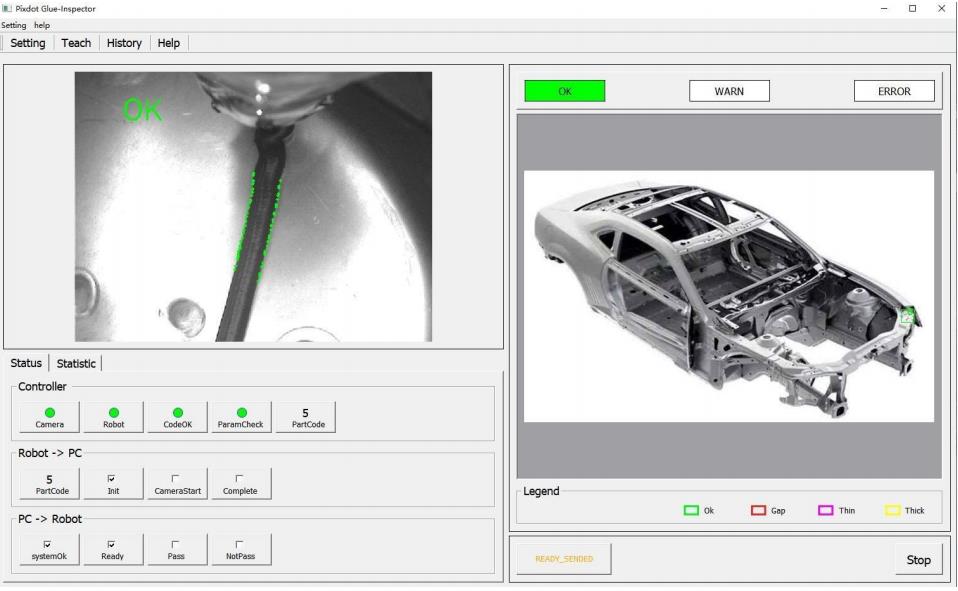

Real-time detection of gluing quality

• Detect the absence, continuity, width, and position of bead

• Supporting gluing speeds up to 1200mm/sec

• Supporting detection of bead defects as small as 1mm

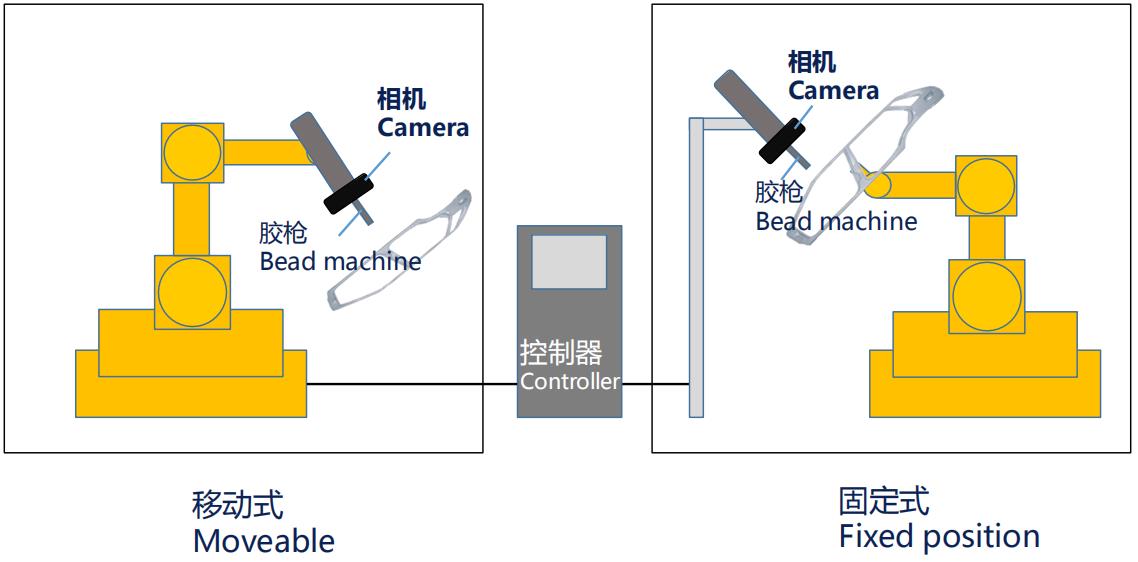

• Supporting 360 ° full-angle detection

• Powerful automatic teaching function

Detection terms

• absence of bead

• continuity of bead

• width of bead

• position of bead

Software functions

• Real-time monitoring of gluing status

• Online teaching

• Automatic guiding repairing defects

• Statistics of gluing

• History traceability

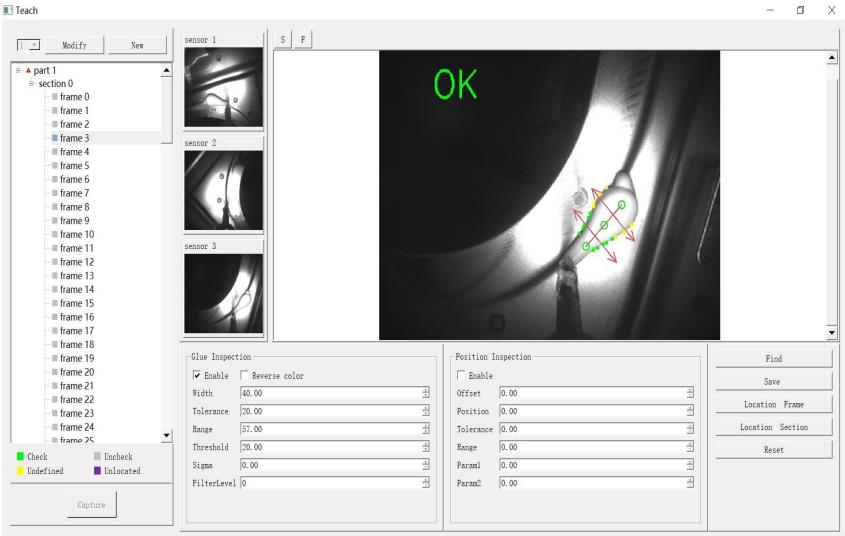

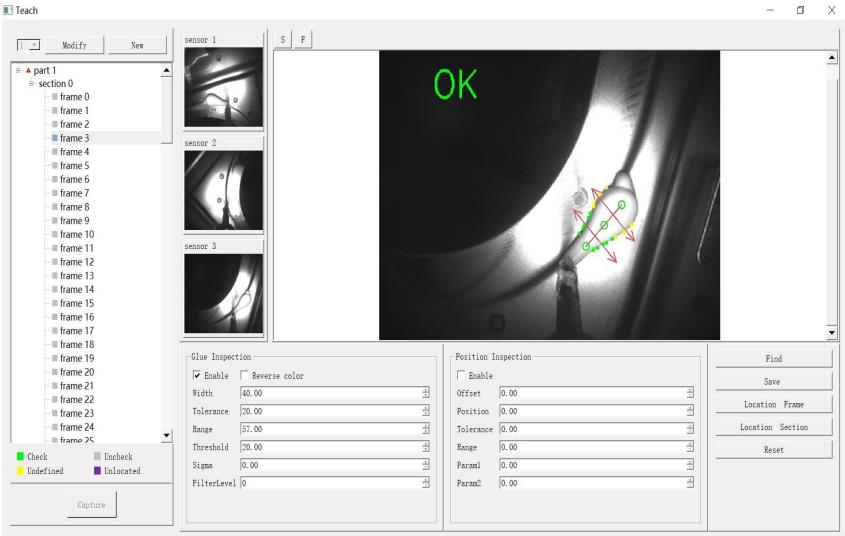

Teaching Introduction

Teaching needs to make template for each frame. The system can automatically configure most parameters to complete teaching quickly.

Configurable Parameters

• Width of bead

• Width tolerance

• ROI

• Gradient threshold

• Filter

• Negative mode

Statistics & History

Statistics

Statistics include: absence, continuity, width and position error of bead, which can be filtered by time and value.Statistics help users identify problems and improve

production processes.

History

The system will store pictures and production data, and can set the storage time.

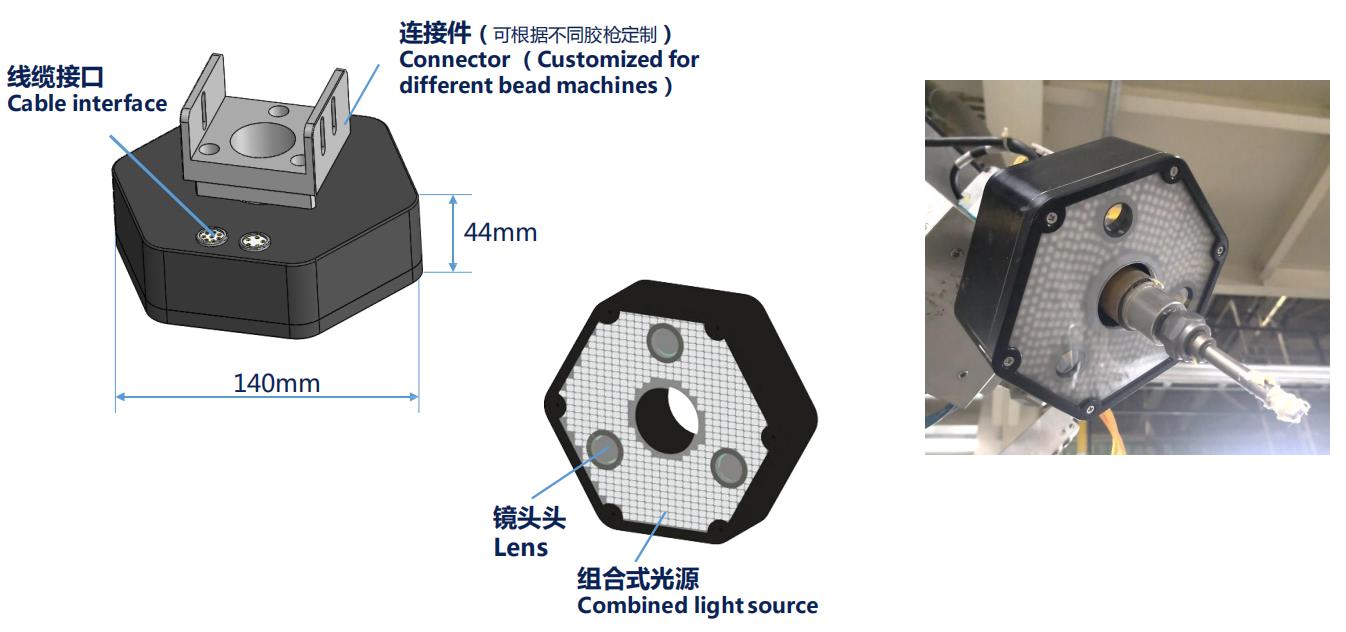

| NO. | Device name | Specifications |

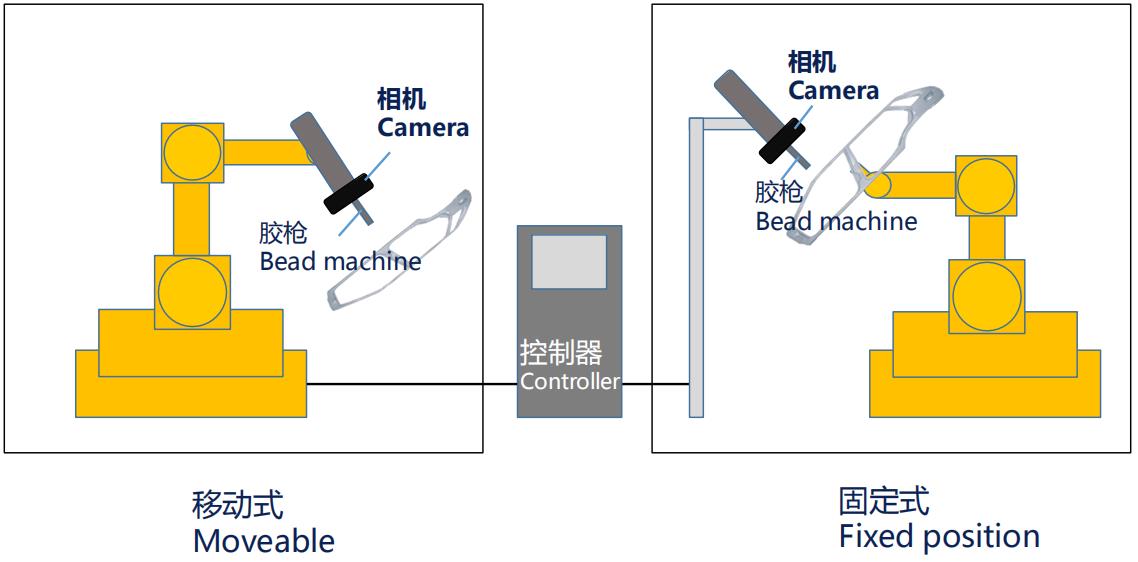

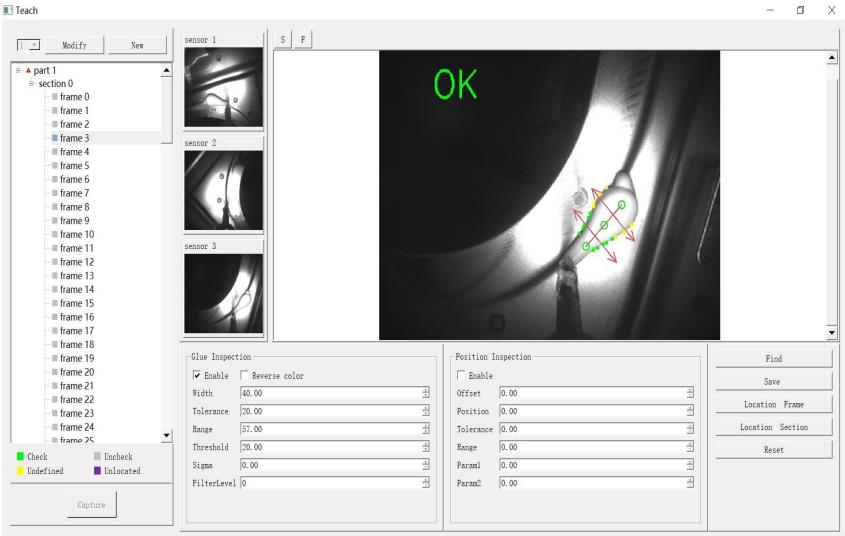

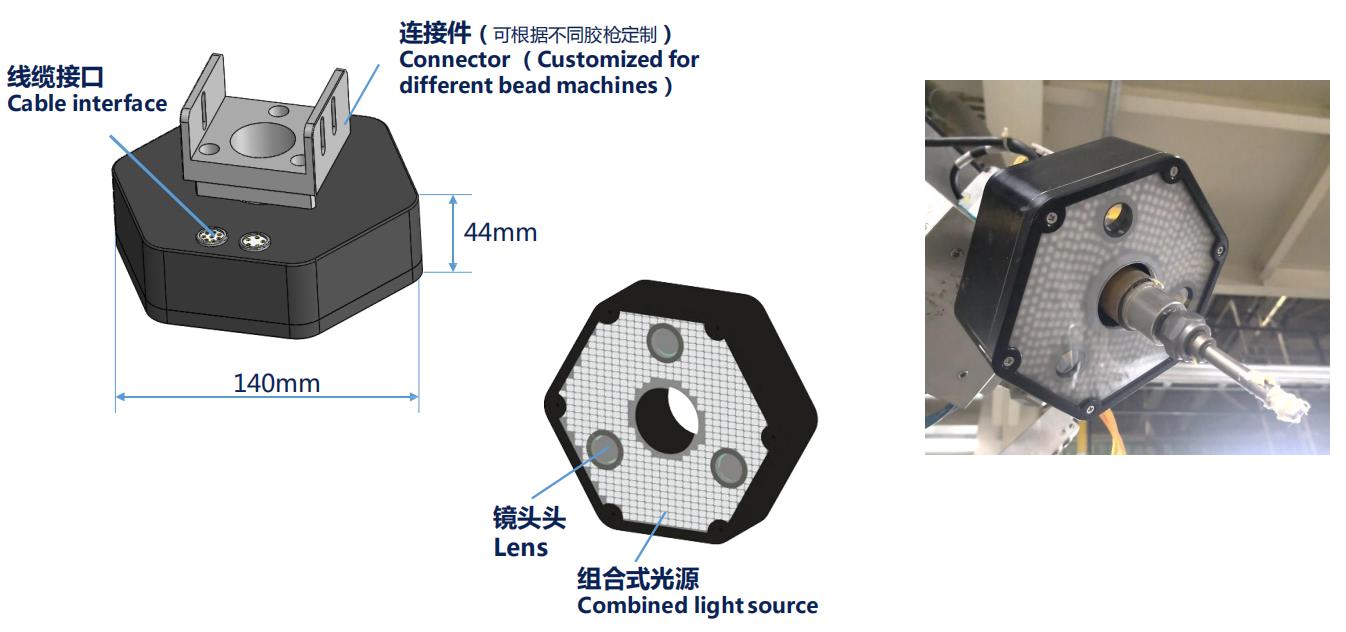

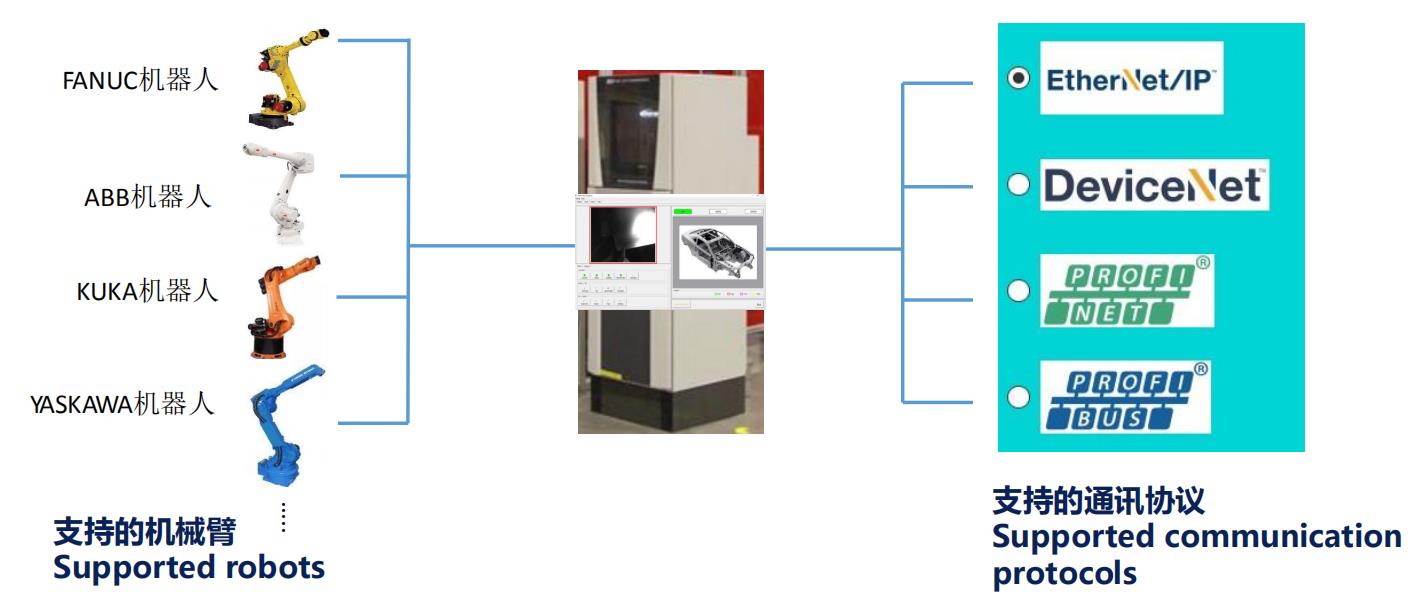

| 1 | Camera | - Trinocular omnidirectional camera - Each sensor supports 1280*960@24fp - Combined strobe light source |

| 2 | Vision System | - Real-time online detection - Teaching - Automatic guiding bead repair - Statistics - Historical tracing |

| 3 | Controller

| - IPC 610 - CPU i5-6500 - 2 Gigabit Ethernet port - 8G RAM - 2T Hard disk - Win7 64bits |

| 4 | Cabinet | - Size H×W×D:1800×600×600 - Air conditioning |

中文

中文 ENGLISH

ENGLISH