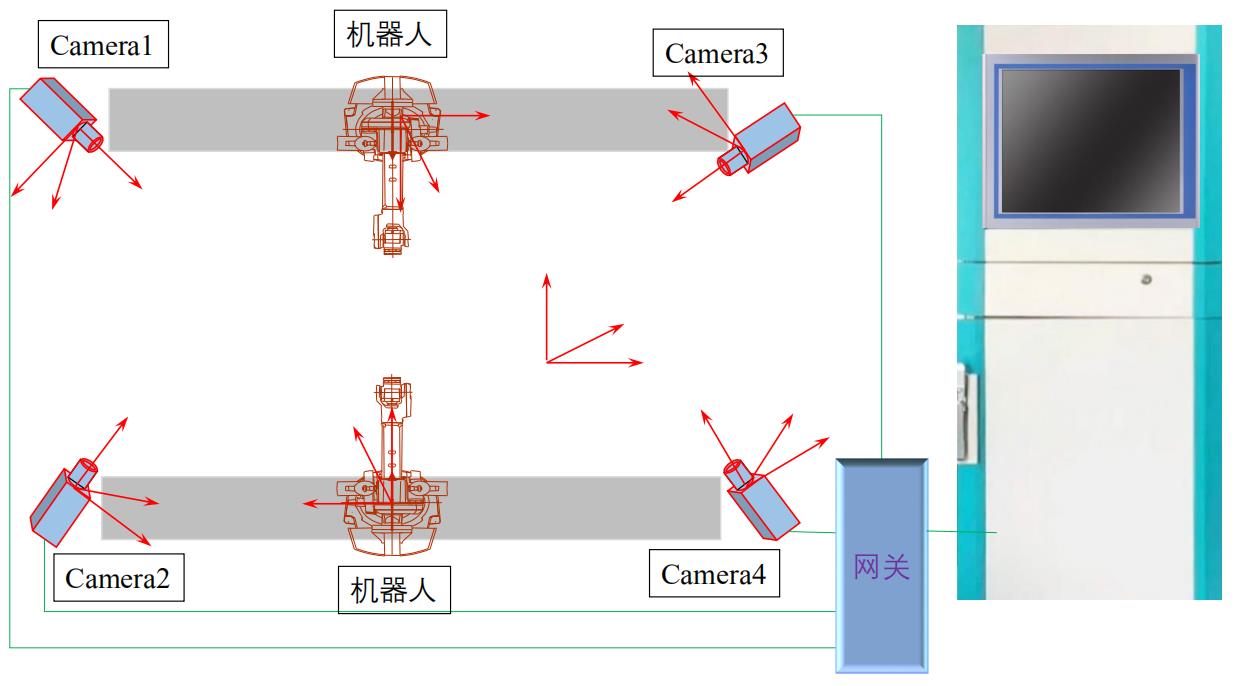

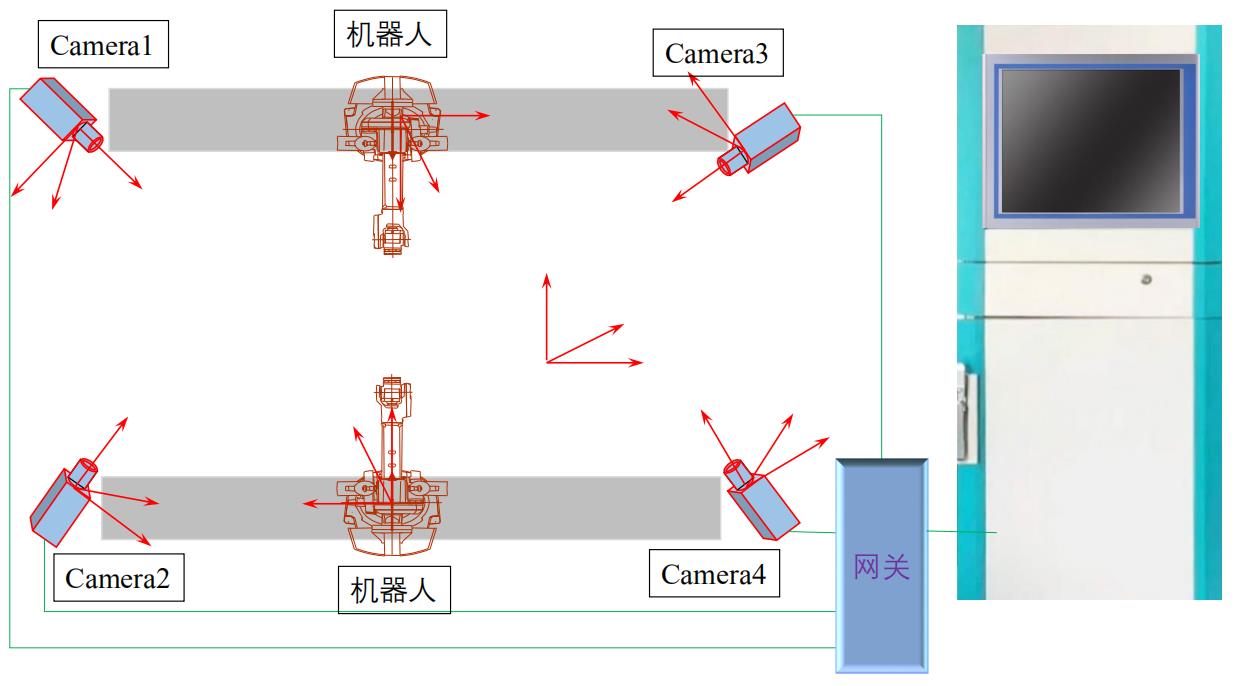

system architecture

The 3D vision vehicle body positioning system is composed of an electric cabinet, an industrial computer, a gateway, 4 + cameras and 4 + light sources.

system function

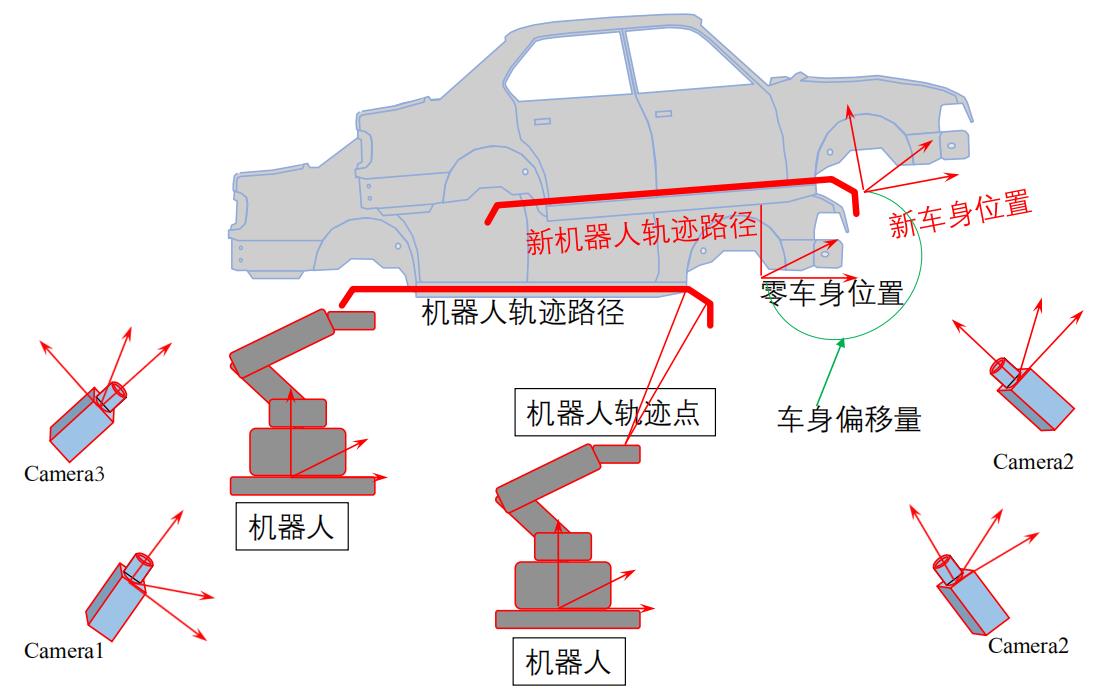

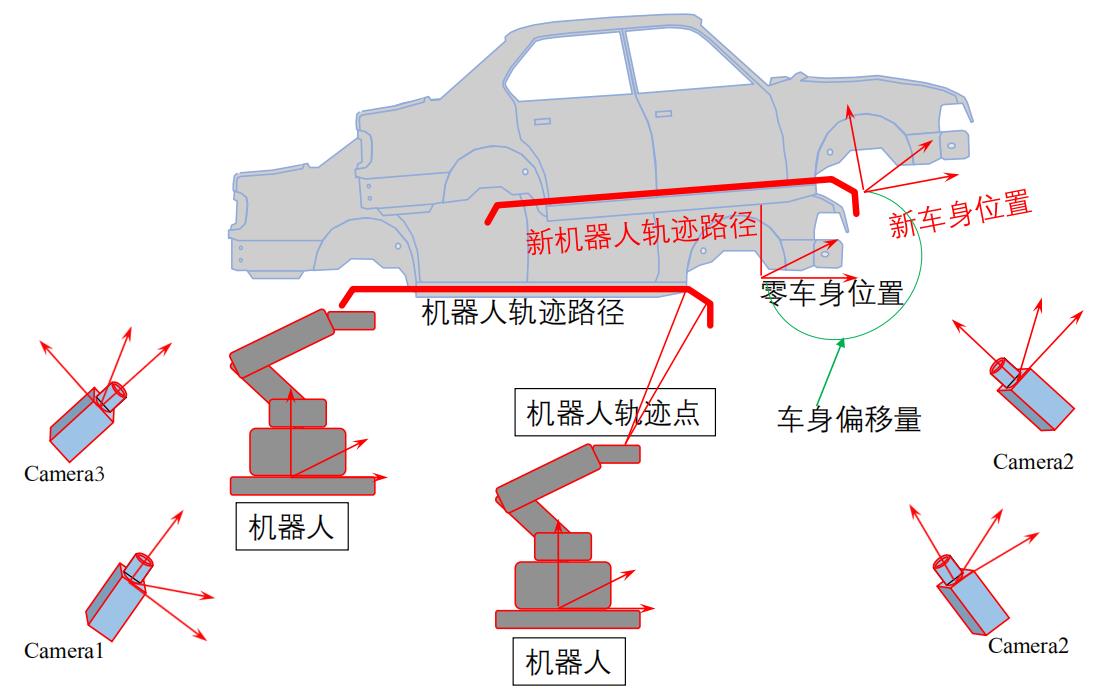

• 3D vision body positioning system, measure and calculate the position offset between the body and the new body, and guide the robot to work on the body (such as gluing, painting, etc.)

• Supports initial position tolerance of up to 150 mm, 10 °

• Support guidance accuracy up to 0.05mm

• Complete the template setting of new model in half an hour

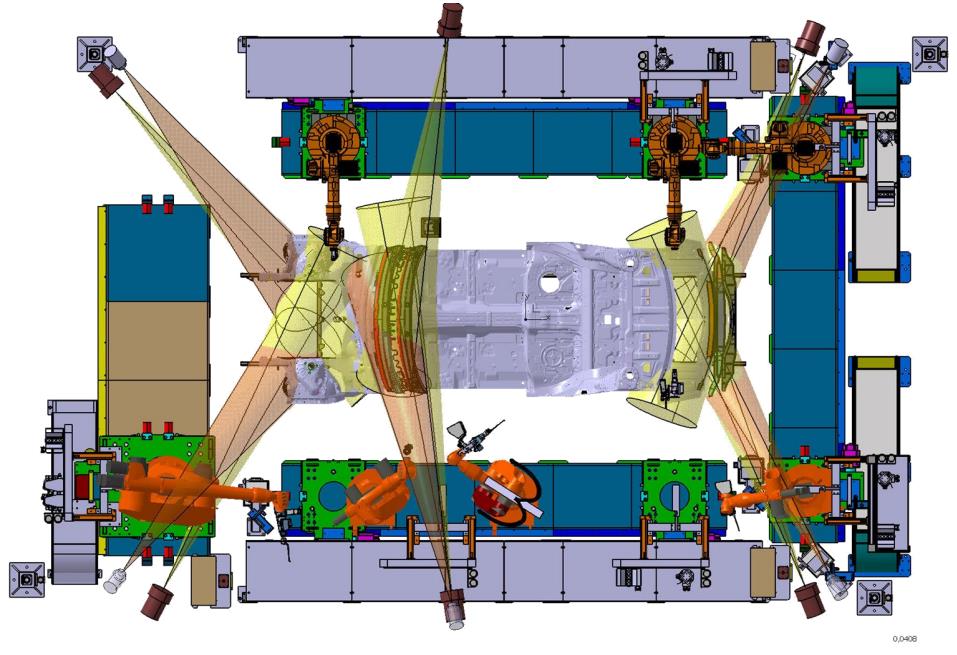

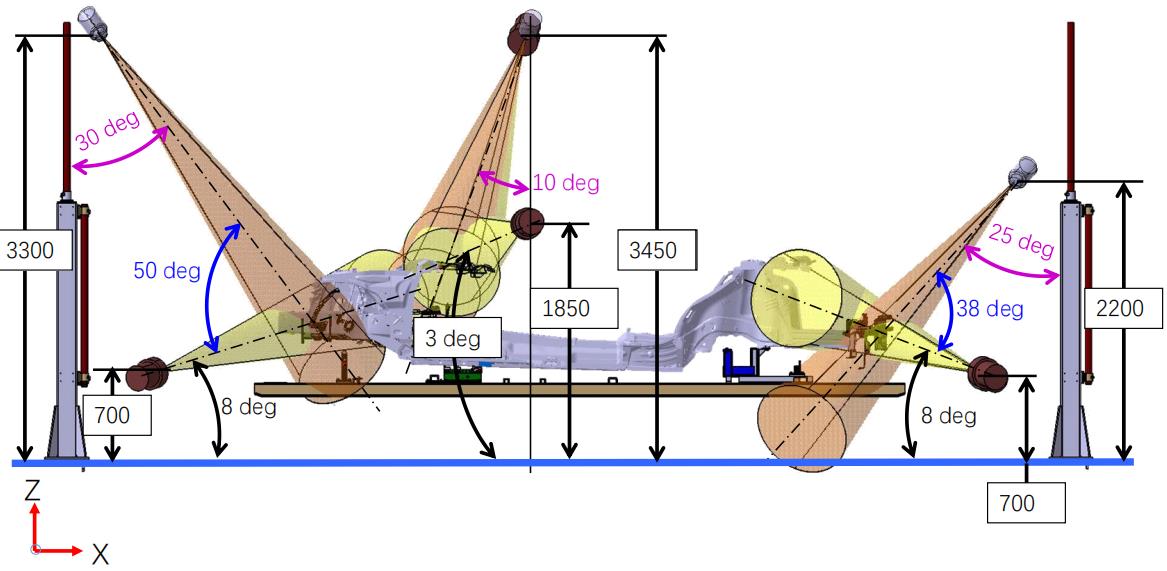

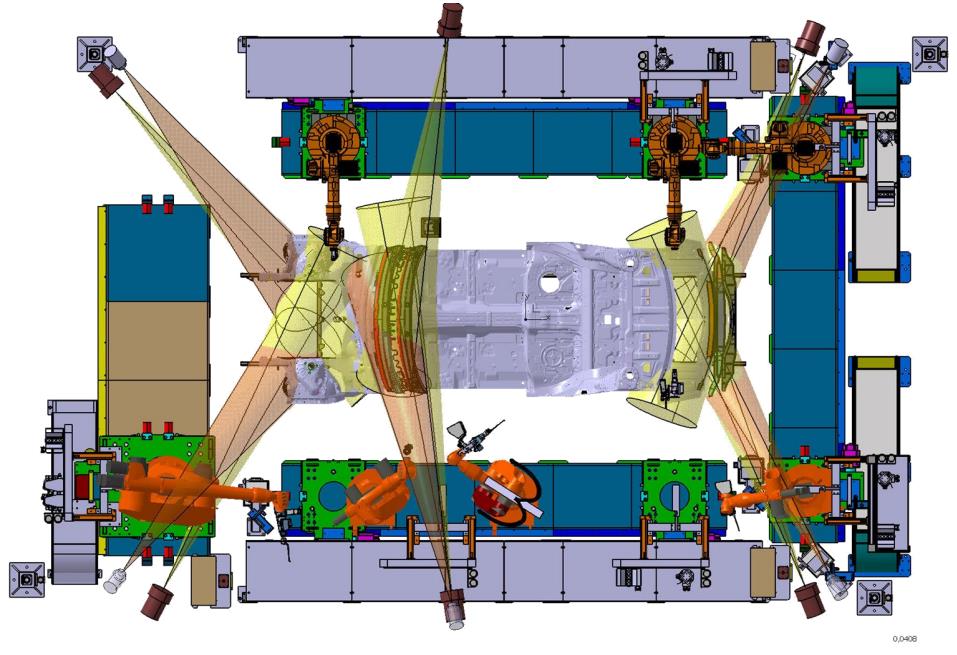

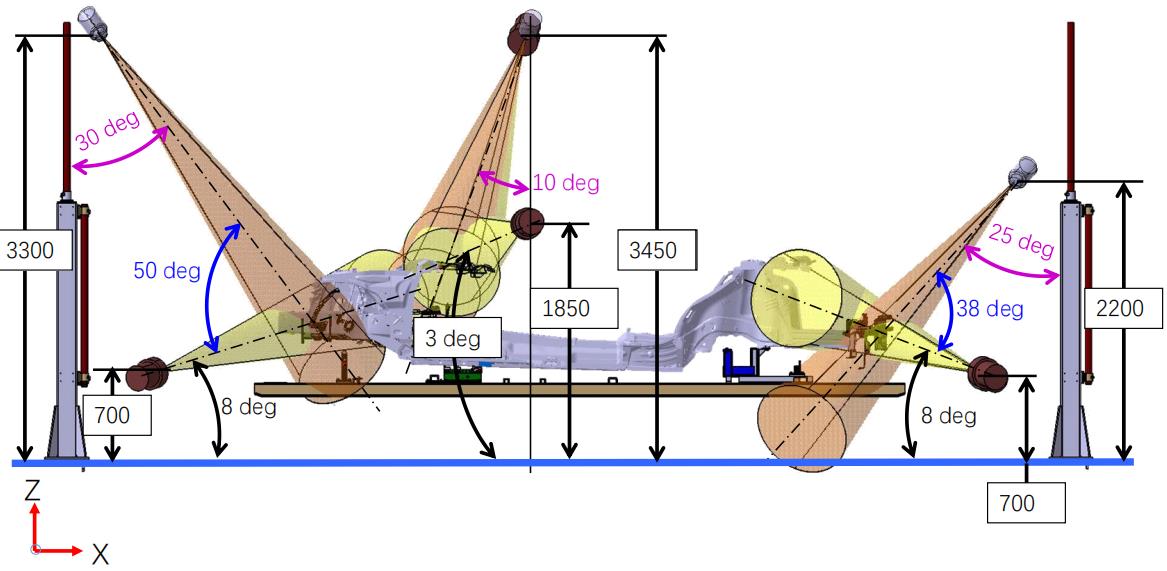

Site layout

The 3D vision vehicle body positioning system is composed of an electric cabinet, an industrial computer, a gateway, 4 + cameras and 4 + light sources.

Installation requirements

The installation position of 3D vision camera and light source meets the best imaging requirements.

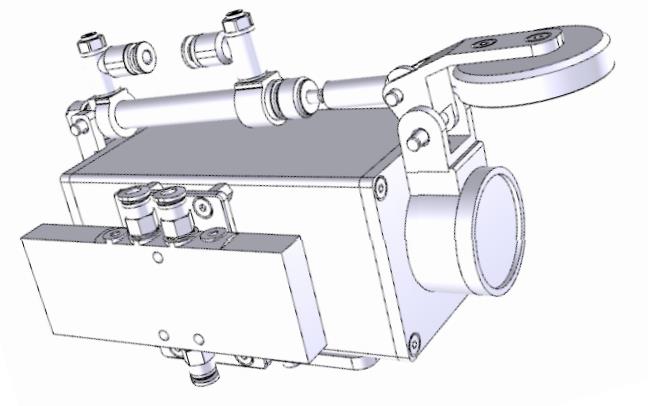

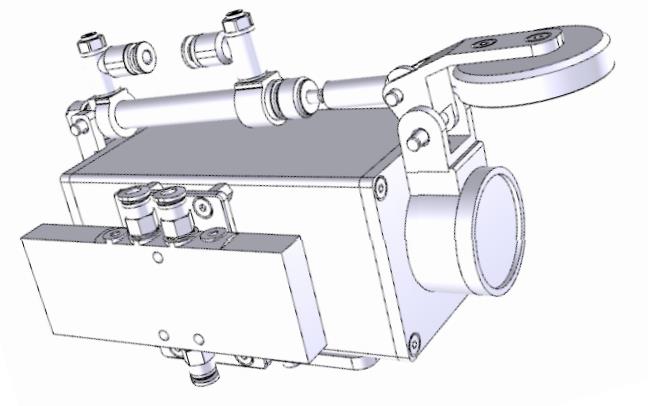

Hardware introduction

Unified hardware management (camera, camera cover, camera flip)

software function

• Feature extraction, AI intelligent extraction technology, change the traditional template technology

• Automatic template extraction

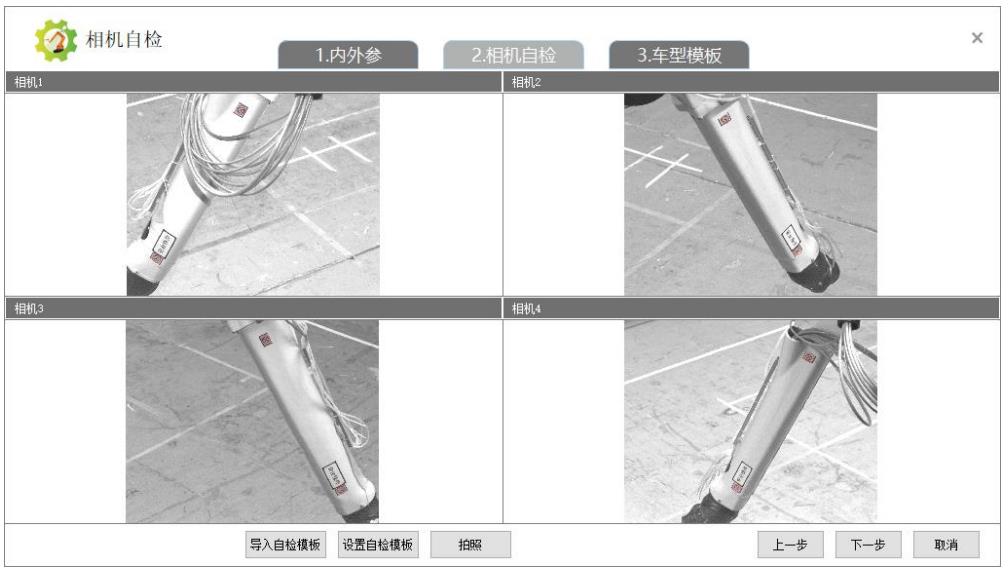

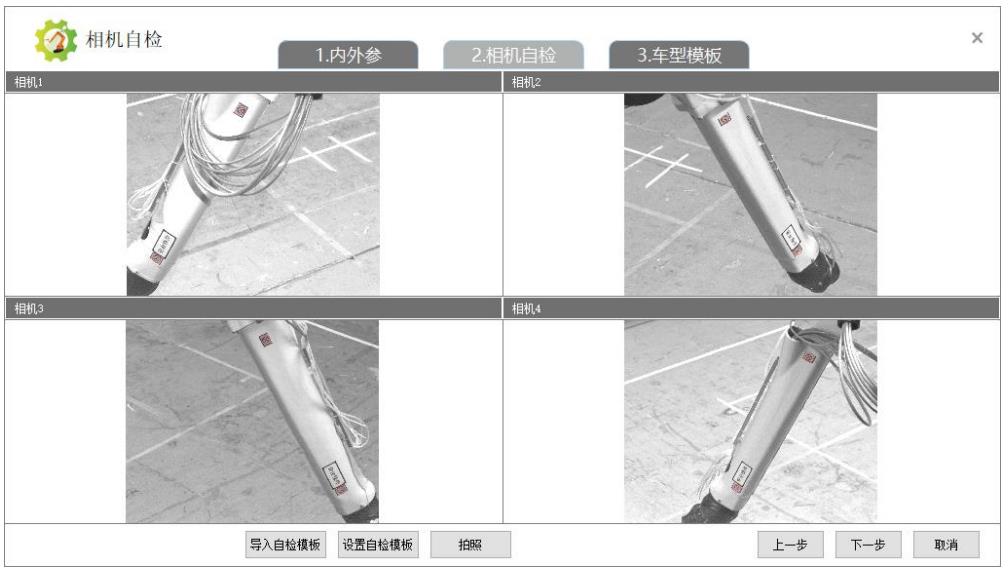

Camera position self check

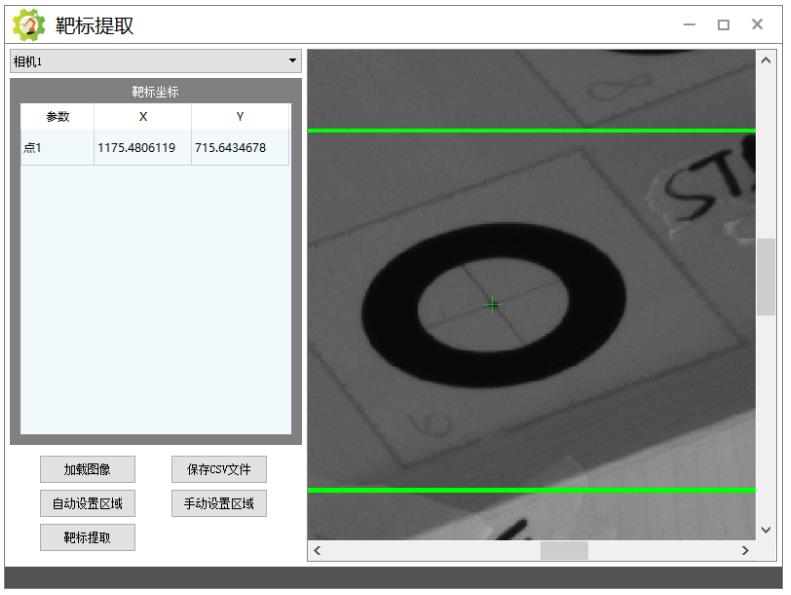

Intelligent contour extraction

Template quality assessment

Teaching aids

History tracing function

Data statistics function

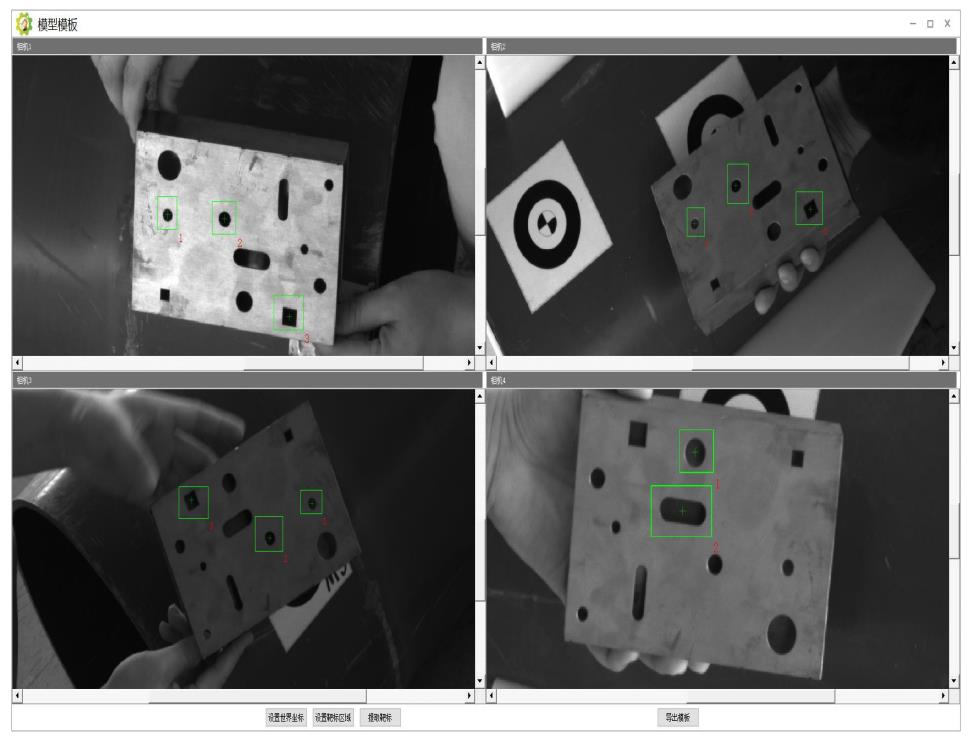

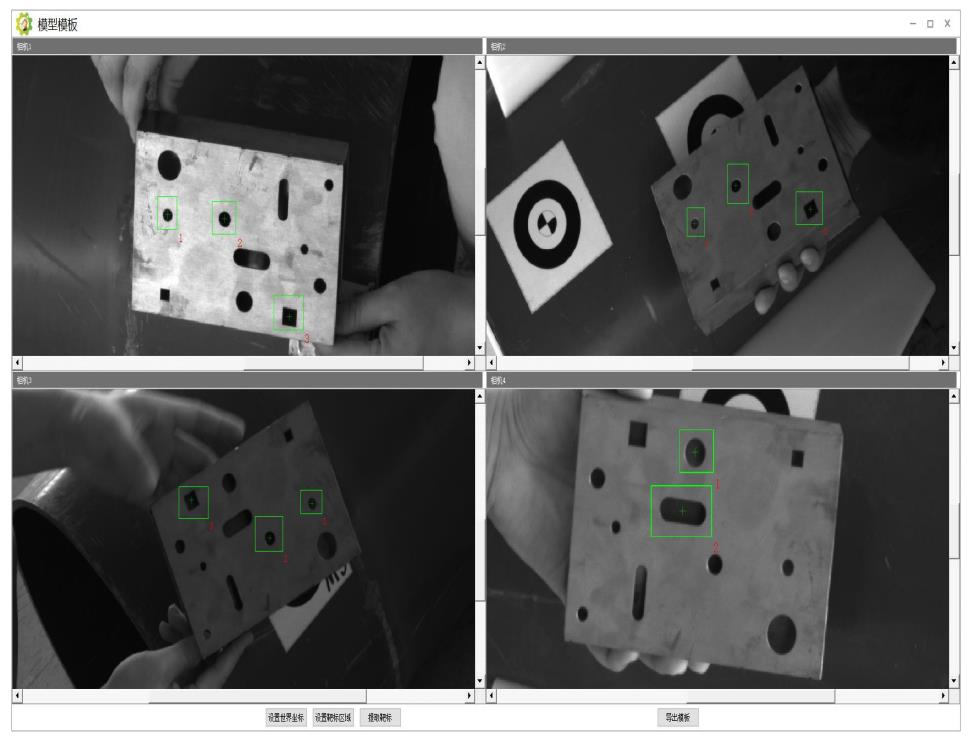

Teaching introduction:

For each kind of parts that need to be grasped, a separate template should be set up. The software can automatically recognize the part features when making the template. During production, the software will compare the 3D position of the material with the template difference to guide the robot to grasp.

characteristic:

• The software will automatically extract the best features by using the selection tool box to select through holes, edges and other areas.

• After the template is made, the software will automatically evaluate the template quality.

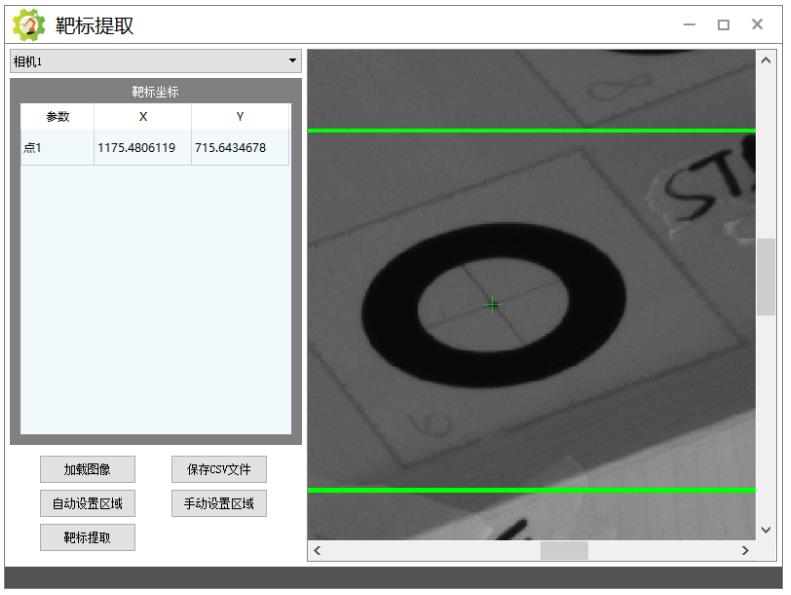

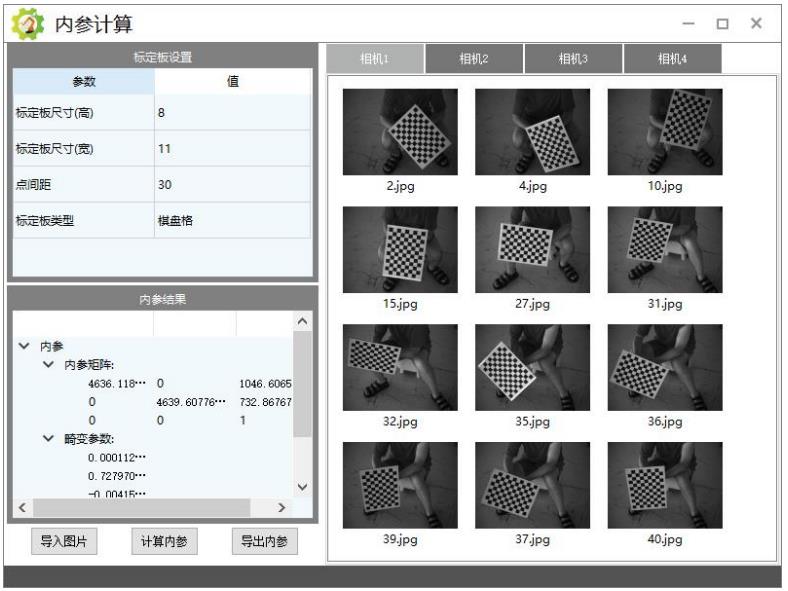

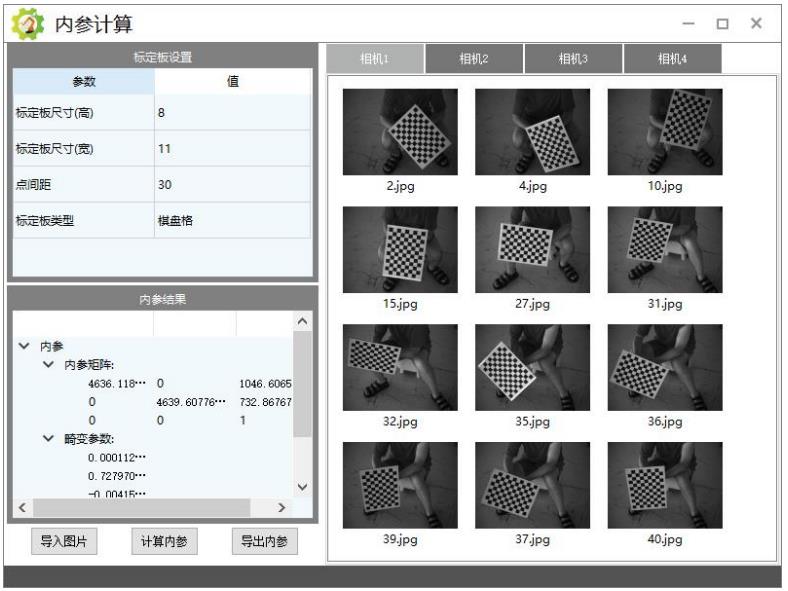

Global calibration:

After the new camera is installed, the camera position needs to be calibrated. Under the guidance of software, the mobile robot can complete the internal parameter calibration by photographing the calibration board from multiple positions.

characteristic:

• The software recommends the best shooting position to maximize the calibration success rate.

• Ensure the measurement accuracy of any point in the camera field of view, that is, the accuracy of feature hole on the edge of field of view.

| NO. | Device name | Specifications |

| 1 | Camera | - camera with 16mm,25mm,35mm Lens - Strobe light source |

| 2 | Vision System | - 3D Robot Vision - Teaching - Historical tracing |

| 3 | Controller | - IPC 610 - CPU i5-6500 - 2 Gigabit Ethernet port - 8G RAM - 2T Hard disk - Win7 64bits |

| 4 | Cabinet | - Size H×W×D:1800×600×600 - Air conditioning |

中文

中文 ENGLISH

ENGLISH